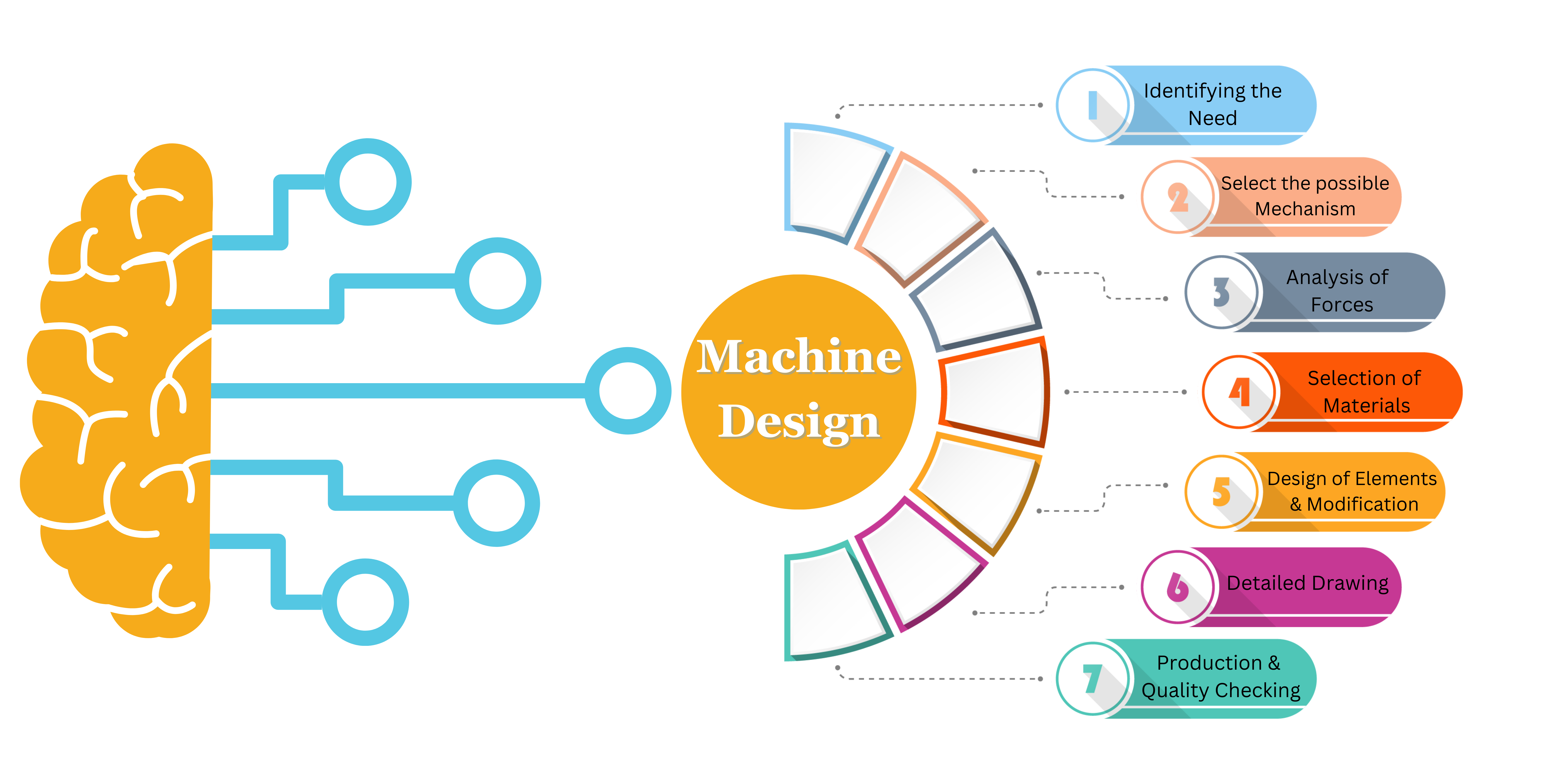

The inventiveness and complexity of machine design and mechanical engineering have advanced significantly as manufacturing technology has advanced.While we all aspire to be at the forefront of innovation, we can also use current technology to start us moving in the right path. Machine elements that once appeared unattainable are now standard in the production sector.The fundamentals of machine design, which can be divided into three groups

• Adaptive

• Design

• Developmental Design

• New Design

It is one of the most fundamental but frequently employed styles of machine design.Don't reinvent the wheel comes to mind. There are frequently pre-existing, widely-accepted machine parts or design elements that could be used to meet your needs.Basic features are used in adaptive design, but they are slightly modified to better suit a specific application.It can be more efficient for firms and engineers to modify technology that has already been shown to work than to try to design a part from scratch.

Similar to adaptive design, Developmental design builds on preexisting ideas and technologies while incorporating fresh features and parts to produce something entirely new.The motorbike, which is essentially the union of a bicycle and a combustion engine, is a common example used in developmental design.The motorbike was undoubtedly a significant advancement in manufacturing technique and machine design, but it is built on the foundation of pre-existing mechanical components.

Even though the vast majority of machine designs will fit into the first two groups, new and distinctive components and technologies are always being developed.These unique inventions would be categorized as New Design, when engineers and designers create something wholly unique.This is much less typical and frequently calls for extensive time, money, and investigation.It is typically more productive and efficient to modify what already exists because we live in a world of shared knowledge and technology, but with the right idea and the right experience, elements in the New Design space can be extremely profitable and advantageous to the manufacturing industry as a whole.

In what kind of environment will your part live? Under what stresses will it routinely be placed? There are many factors that can help or hinder a parts performance (temperature, moisture, dust/debris, impact, range of motion, etc.) When it comes to mechanical design, the more research an engineer can do up front the better. A machine element that works great in the snow could fail in the desert, and these varying conditions will need to be accounted for.

With a keen understanding of the stresses at play in a particular environment, the next decision in the machine design process is what material to use in manufacturing a part. Certain metals are more resistant to corrosion and warping. Different plastics hold up better to heat and friction. If weight is a factor, there are a number of high-strength light-weight materials available, but they come at a cost. These are all factors to keep in mind throughout the machine design process.

Before a part is completely designed, it is important to have a firm understanding of the manufacturing technology at one’s disposal to ensure that a part can be produced effectively and affordably. Mechanical engineers will often work closely with their machine shop to discuss challenges or limitations in their design elements, and to brainstorm potential areas of improvement (machine availability, required tolerances, bend geometry, etc.) The most mind-blowing design in the world could look great in a CAD model, but if it doesn’t do a lot of good if it can’t actually be machined.

WhatsApp us