Overview

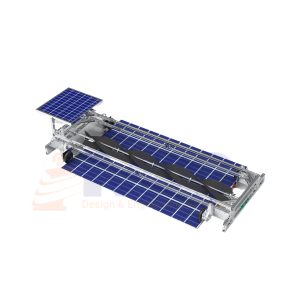

iMAC Design, being a one-stop solutions provider, offers complete Product engineering services from Idea to Revenue Stage.

As a product design and development firm, we use our human-centered methodology to solve any engineering challenge. Whether creating new products and services or improving existing ones, we assist at all stages of a product’s life cycle. Our cross-disciplinary specialists, researchers, designers, and engineers leverage their deep understanding of multiple industries and technologies to spark creative and innovative solutions.

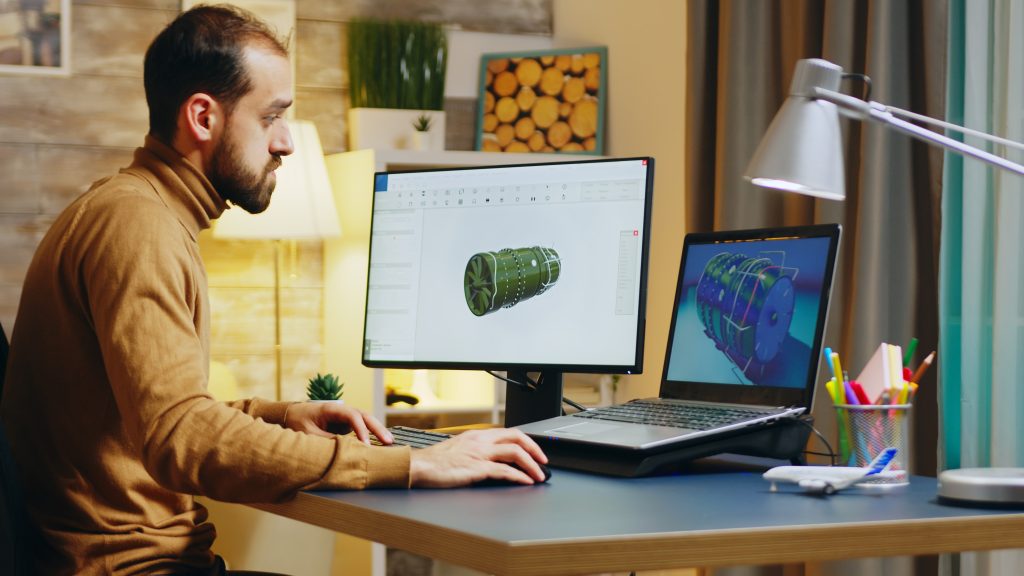

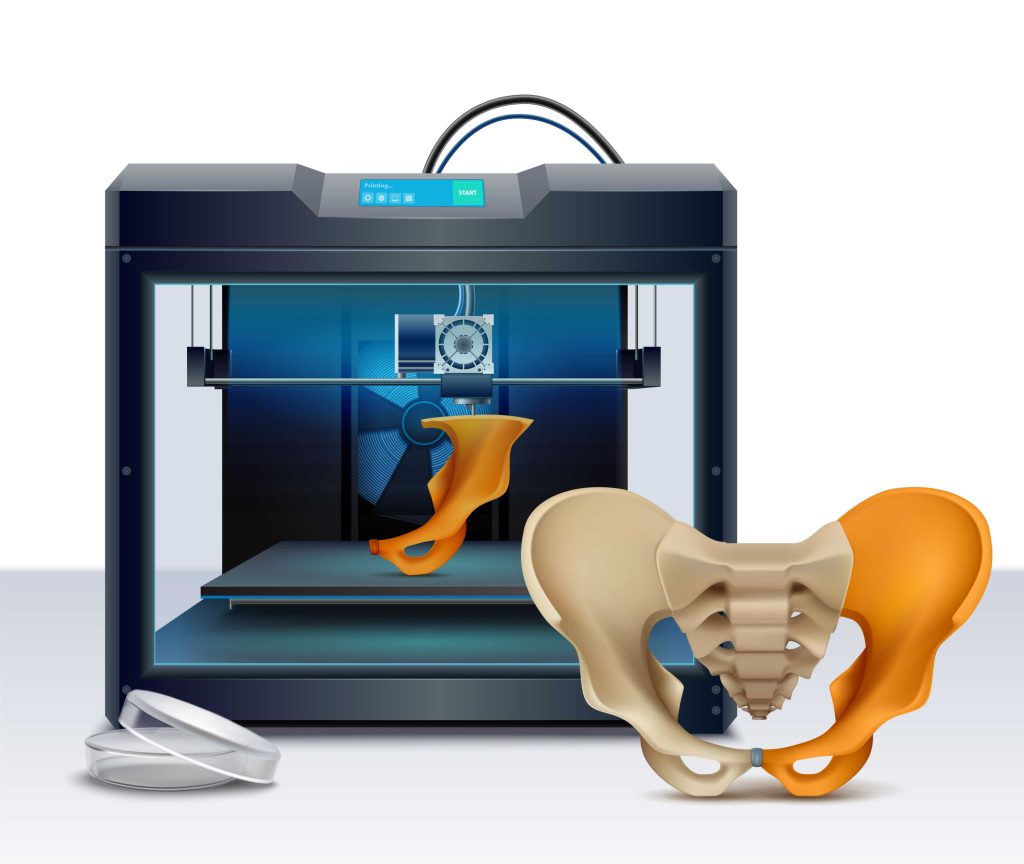

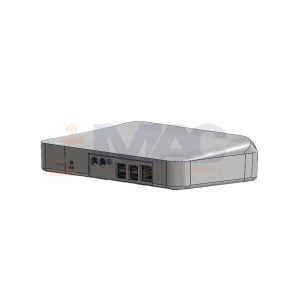

Our product engineering team takes a design solution and prepares it for manufacturing and launch. Our expertise and engineering services include CAD development, BOM creation, CTF drawings, prototyping, and testing as well as mechanical problem-solving, materials selection sourcing, and manufacturing support.

Our approach is integrative. Because we are also a design and development firm, our engineering team takes a holistic view of all projects. This view enables us to uniquely engineer designs so that they can be scaled on a cost-effective basis to ensure profitability and success. We also work with startups to engineer challenging new concepts or ideas.